Sheet Metal Working

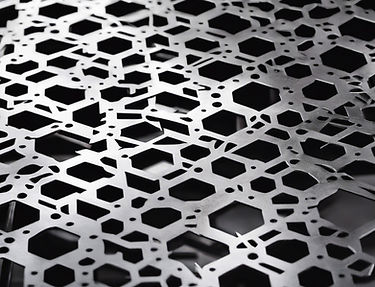

Laser Cutting

Laser cutting is a method of cutting a design from metal sheets using a highly focused laser to melt material in a localized area. The process meets the tightest tolerances by using a precise cutting surface guided by computer-aided design. Since laser cutting is an extremely precise and accurate process, the cuts it creates require very little deburring, making fabricating components with intricate details easier.

Stamping

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal.

Bending

Bending is one of the most common sheet metal fabrication operations. Also known as press braking, the method is used to deform a material to an angular shape. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic deformation. Only then can you get a lasting result in the form of a bend. We recommend a minimum bend radius of 1t for all sheet metal parts. Thus, the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, the minimum bend radius should be 1 mm. Bending plates with a thickness above 8 mm is not recommended.

Deep Drawing

Deep drawing is the process of forming sheet metal by using a punch to radially draw the metal into a forming die. The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces that transform the shape under high pressure. Deep drawing retains the thickness of the sheet metal material and produces highly accurate, repeatable components.

Deep drawing is a cost-effective process for manufacturing applications requiring high precision and high volumes of parts. Deep drawing also works well for products of lightweight material that require a significant amount of strength

Materials

There are many different possibilities in material choice. In most cases, we use this technique for the production of steel and stainless steel parts. Almost all alloys are possible and our material scientists, can advise you on the most suitable material for your application.